Customize Lithium Battery Pack Manufacturer

Powering Industrial, Medical, and Energy Storage Applications with Reliable Battery Solutions

- 15+ Certified Engineers Delivering Precision-Crafted Battery Packs

- ISO9001 & UN38.3 Certified Production for Global Compliance

- 99% On-Time Delivery with Rigorous Quality Assurance

- Custom 12V–72V Lithium Battery Packs for Industrial & EV Applications

Partner Brands

Trusted by Industry Leaders

Battery Pack Product Categories

Lithium-ion Battery Pack

Customizable Lithium-ion Battery Pack designed for various applications including medical devices, robotics, and industrial equipment.

LiFePO4 Battery Pack

Safe, long-life lithium iron phosphate packs ideal for solar energy storage, RVs, and backup power systems.

Lithium Polymer Battery

High energy density LiPo packs perfect for drones, handheld devices, and compact electronics.

Energy Storage Solutions

Complete battery energy storage systems for residential, commercial, and industrial use.

Custom Lithium Batteries for Different Applications

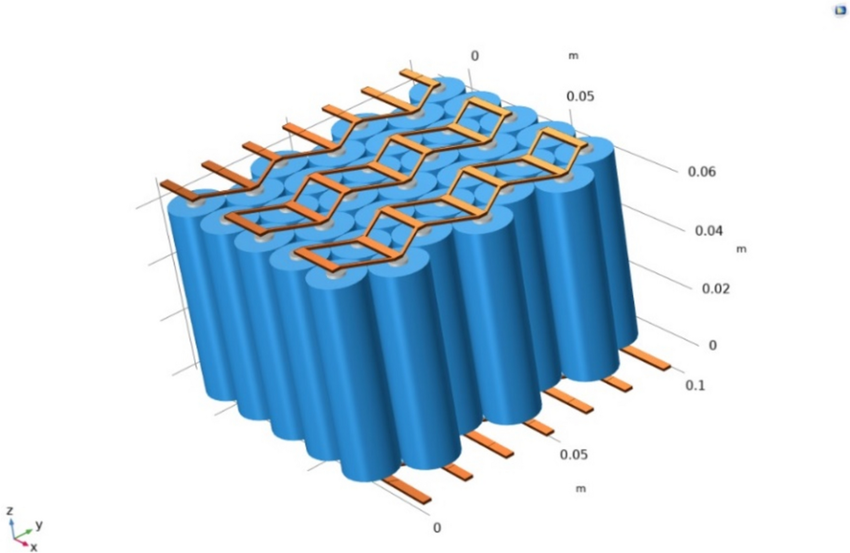

What is Battery Pack Machining?

Battery pack machining refers to the precision manufacturing process used to create custom housings, brackets, busbars, cooling plates, and other components required for battery pack assembly. Using CNC machines, laser cutting, and milling equipment, these parts are shaped with high accuracy to ensure proper fit, thermal management, and mechanical protection for lithium battery modules. Materials typically include aluminum, copper, and engineering plastics, all chosen for their conductivity, strength, and thermal performance.

High-quality battery pack machining is essential for applications in electric vehicles, energy storage systems, robotics, and industrial equipment—where consistency, safety, and performance are critical.

Jetray Global Battery Network

Since 2012, Jetray has been the trusted partner for custom lithium battery packs. We specialize in designing and manufacturing high-performance battery systems for industrial equipment, energy storage, and electric mobility projects, ensuring safe, reliable, and cost-effective solutions for every application.

12+ Years

Custom Lithium Battery Pack Experience

500+ Projects

Delivered for Industrial, Energy & Mobility Sectors

95%

Customer Repeat Order Rate

30+ Countries

Trusted by Global OEMs & Project Developers

How to Cooperate with Jetray

We enable your project to get reliable lithium battery packs with excellent performance at a very competitive cost.

Project Consultation

Share your project requirements, battery specifications, and application scenarios with our team.

Solution Design & Quotation

Our engineers provide a tailored battery pack design and detailed quotation based on your needs.

Sample & Validation

We produce samples for testing and help you validate performance, safety, and compliance.

Mass Production & Delivery

After approval, we proceed with full-scale production and deliver reliable battery packs on time.

Battery Pack Solutions: Design-Based Customization

As a professional battery pack manufacturer, we provide fully customized solutions based on your power requirements. Our engineers analyze your specifications, select suitable cells and BMS, and design the pack structure to deliver safe, reliable, and high-performance battery packs tailored to your applications.

Complete Service

During the entire production process, we provide regular updates on pack assembly and testing progress. After quality inspection, we share pictures and test reports for your approval. We also offer packaging photos and videos before shipment to ensure everything meets your expectations.

Efficiency and Speed

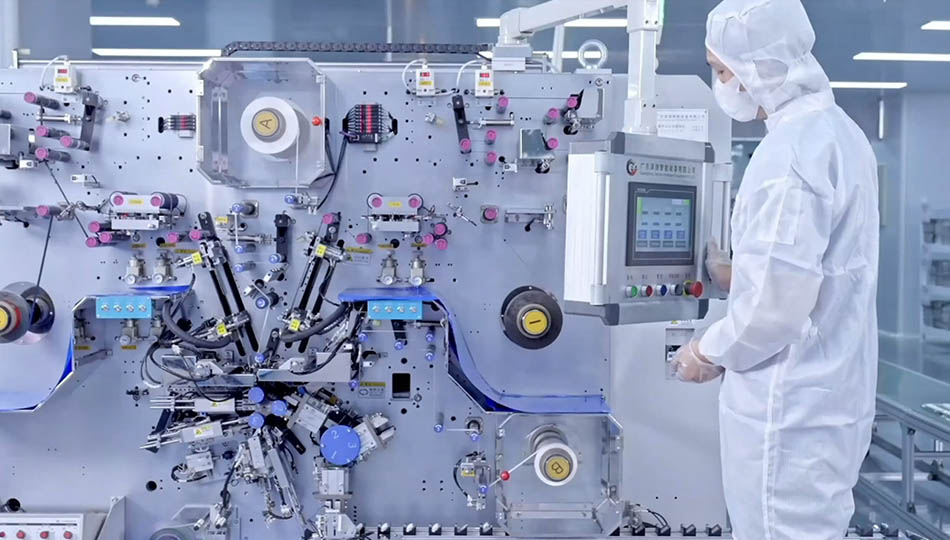

We provide quick quotes within 1-12 hours and ship battery packs in bulk within 10-20 days for most projects. With advanced production lines and automated welding equipment, we deliver consistent quality and accelerate your product’s time to market.

How Do We Ensure Consistent Battery Pack Quality?

We follow strict design review, cell matching, and quality control processes to guarantee every battery pack meets your performance and safety requirements. With our advanced production equipment and professional engineering team, we deliver stable and reliable power solutions for your projects.

Engineering Expertise & Smart Production

Our experienced battery engineers work closely with you to understand your power requirements and design safe, efficient packs. Automated welding and assembly lines ensure consistency and minimize human error.

- Dedicated Engineer Support from design to mass production

- Regular Production Updates every 3 days with pictures and reports

- Automated Welding & Precision Assembly for consistent quality

Strict Quality Inspection Standards

Each battery pack undergoes multiple tests, including cell sorting, BMS function check, charge/discharge cycling, and insulation tests. Only fully compliant packs are cleared for shipping.

- Cell matching and balancing before assembly

- Electrical and safety performance test after production

- ISO 9001 and UN38.3 certified processes

After-Sales Service & Support

We stand behind every pack we build. If any issue arises, our team responds quickly to resolve it, ensuring minimal impact to your project timeline.

- 30-Day Quality Guarantee for all battery packs

- 1–3 Working Days Response to any technical issue

- Replacement, rework, or refund based on actual situation

Join over 1,000 companies that trust Jetray

Why not listen to what our global partners have to say about our battery pack solutions? These are real insights from real projects.

John Miller

United States

Custom Lithium Battery Packs for Robotics

“We have been working with Jetray for over 2 years for our autonomous robot projects. Their engineering team provided detailed battery design and BMS programming support, ensuring long runtime and stable performance. We trust their quality and fast response.”

Sophie Zhang

Germany

Energy Storage Packs for Solar Projects

“Our company needed reliable 48V battery packs for off-grid solar installations. Jetray delivered safe, certified packs on time, with complete testing reports. Their professionalism and after-sales support make them our preferred supplier.”

David Brown

Australia

Custom EV Battery Solution

“We had very specific voltage and current requirements for our electric vehicle prototype. Jetray helped us from cell selection to enclosure design. The packs passed all safety tests, and we will continue our collaboration for mass production.”

FAQ

1. Can Jetray customize lithium battery packs for my specific application?

Yes. We tailor battery packs to your voltage, capacity, size, shape, discharge rate, and communication needs (CAN, SMBus, etc.), for sectors like EVs, ESS, medical, and more.

2. What is the typical MOQ for custom lithium battery packs?

Our minimum order quantity is 100 pcs for prototypes. For mass production, MOQ starts at 500–3000 units, depending on your requirements.

3. How long does it take to develop a custom battery pack?

Prototyping usually takes 4–6 weeks. We offer expedited services for urgent projects.

4. What certifications do Jetray’s batteries support?

We provide batteries compliant with UN38.3, IEC62133, CE, RoHS, and MSDS. Additional certifications can be arranged upon request.

5. Can Jetray integrate a smart BMS into my battery pack?

Absolutely. We design and embed BMS with functions like overcharge protection, temperature monitoring, and real-time communication (CAN/RS485).