Custom Lithium-ion Battery Pack Manufacturer in China

Jetray offers custom lithium-ion battery packs (12.8V–72V) with automotive-grade cells and smart BMS. Supporting 18650, 21700, and prismatic cells, our packs deliver 3,500 cycles, work from -20℃ to 60℃, and can be tailored for capacity, size, and discharge rate.

Customized Service

Tailor-made voltage, capacity, and configuration to match your application.

Long Cycle Life

Built with brand-new Grade A cells, up to 3,500 cycles for lasting performance.

High-Rate Charge & Discharge

Supports fast charge and high current discharge to meet demanding power needs.

Product List

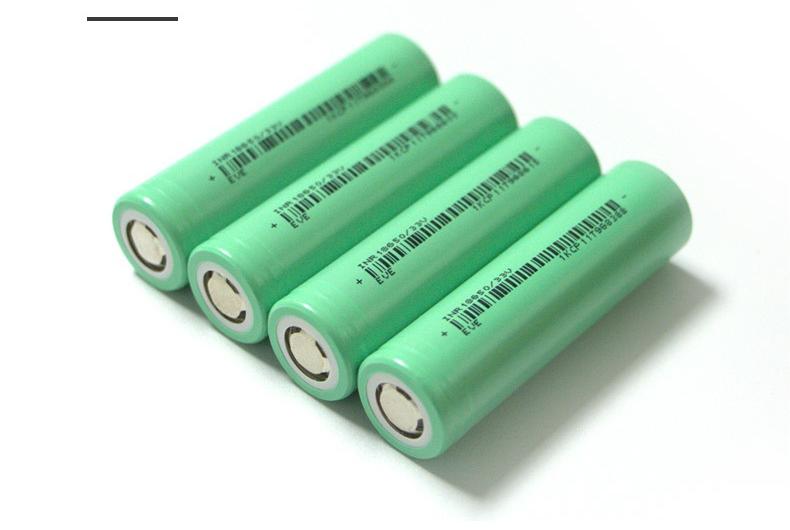

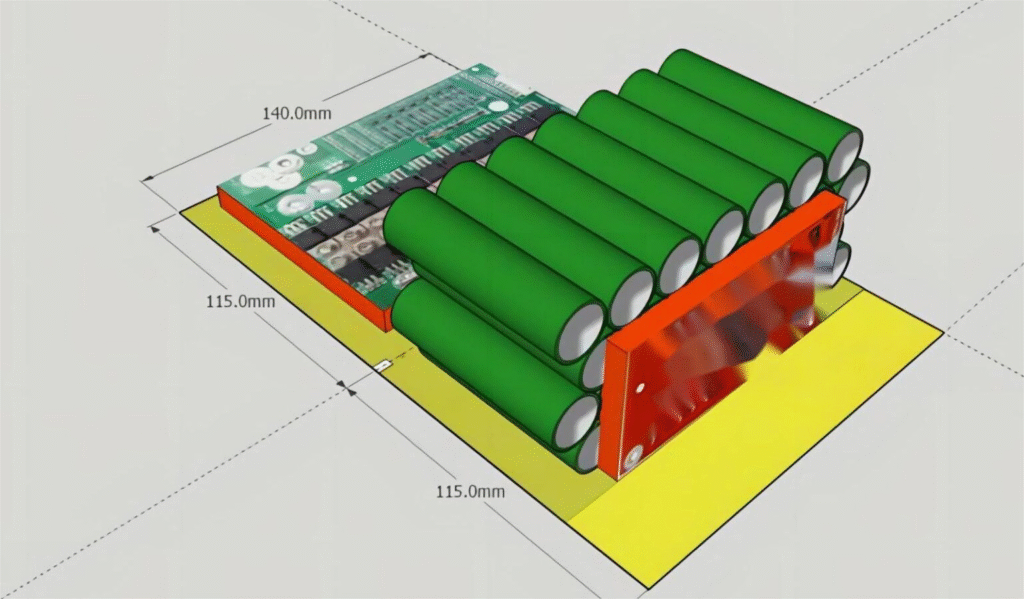

Engineering & Cell Selection

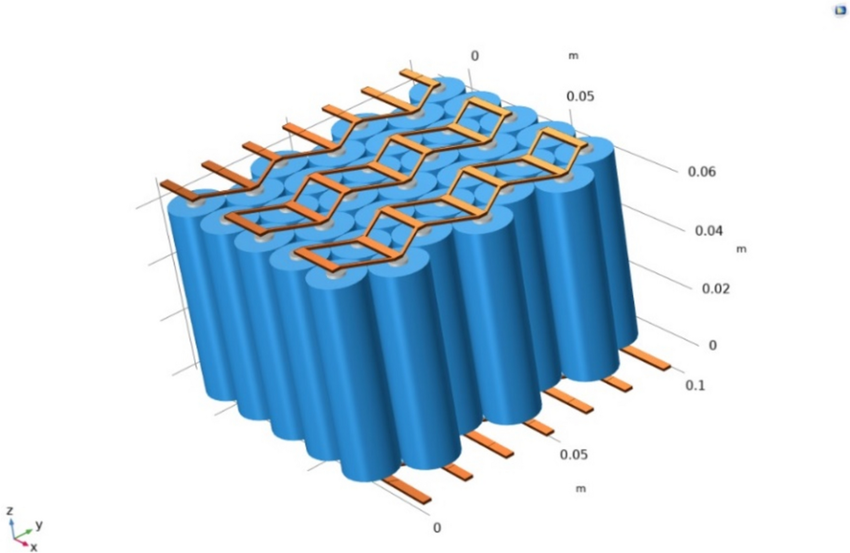

Jetray carefully selects automotive-grade 18650, 21700, and prismatic cells, performing strict matching of voltage, capacity, and internal resistance. Our engineering team uses advanced 3D modeling to design the pack layout and BMS configuration, ensuring optimal performance and safety.

Professional Assembly & BMS Integration

In Jetray’s ISO-certified workshop, cells are spot-welded or laser-welded and integrated with smart Battery Management Systems (BMS) for protection, balancing, and communication (CAN/RS485). The pack is sealed in durable, IP-rated enclosures to meet demanding environments.

Quality Testing & Global Compliance

Each pack undergoes Jetray’s rigorous testing process—charge/discharge cycling, thermal stress, vibration, and drop tests—to guarantee compliance with CE, UN38.3, and international standards before secure packaging and worldwide delivery.

Why Choose Jetray Lithium-ion Battery Pack

Battery Safety

Every pack is designed with automotive-grade cells and smart BMS to ensure safe operation, including overcharge, over-discharge, and short-circuit protection.

Certifications

Our lithium-ion battery packs can meet global standards such as UN38.3, CE, UL, and IEC62133, helping your products comply with international regulations.

Battery Quality

Strict QC process and cycle-life testing guarantee up to 3,500 reliable charge cycles and consistent performance even in -20℃ to 60℃ environments.

Customer Support

From design consultation to after-sales service, Jetray provides full technical support and fast response to keep your projects on track.

Customizable Options for Lithium-ion Battery Packs

Cell Type & Configuration

- 18650 / 21700 cylindrical cells, prismatic cells, pouch cells

- Series / parallel configuration to reach required voltage & capacity

Voltage & Capacity

- 12V / 24V / 36V / 48V or custom voltage systems

- Capacity from a few Ah to hundreds of Ah depending on application

BMS & Communication

- Smart BMS with protection features (overcharge, overdischarge, short circuit)

- CANBus, RS485, UART communication options for system integration

Enclosure & Protection

- Plastic or metal housing, custom dimensions

- IP-rated enclosures (IP54, IP65, IP67) for dustproof and waterproof requirements

Output & Connectors

- Custom terminals, cables, and plug types (Anderson, XT, aviation connectors)

- Fuse and circuit breaker integration for extra safety

How Jetray Builds Your Lithium-ion Battery Pack

Share Your Requirements

Tell us the voltage, capacity, size, discharge rate, and application for your custom lithium-ion battery pack.

Design & Prototype

Our engineers create the battery design (cells + BMS + structure) and build a prototype for testing.

Testing & Optimization

We run safety, performance, and cycle-life tests, then fine-tune the design to match your needs.

Mass Production & Delivery

After approval, we proceed with full-scale production and deliver reliable battery packs on time.

Frequently Asked Questions

Q1: Can you customize the voltage and capacity?

Yes, we design custom lithium-ion battery packs from 12.8V–72V (or higher) with tailored capacity, size, and discharge rate (3C–10C) to fit your application.

Q2: What cell types and brands do you use?

We work with 18650, 21700, and prismatic cells from trusted brands like EVE, CATL, Samsung, and LG to ensure performance and safety.

Q3: What is the cycle life of your battery packs?

Up to 3,500 charge/discharge cycles at 80% capacity retention, depending on cell type and operating conditions.

Q4: Do you provide BMS and communication protocol support?

Yes. Our smart BMS includes protection features and supports CANBus, UART, RS485, and SMBus communication options.

Q5: What is your lead time and MOQ?

Prototype samples take 2–4 weeks, mass production 4–6 weeks. MOQ is flexible depending on design complexity.